Helical Thread Repair Kits

Helical Thread Repair Kits

Chrislynn Repair Kits contain everything needed to complete your repair job except a drill bit. This includes a high-speed steel STI plug tap, a combination installation/tang break off tool, and a generous quantity of inserts, in a length equal to one and a half times the diameter of the insert. These kits are available in metric sizes from M2 to M64, and in American sizes from 2-56 to 1-1/2. Larger 8-Pitch sizes up to 3-1/2 are also available. Pipe Thread, Spark Plug and Left-Hand Thread Kits and Refill Inserts are also available.

The Precision insert system was devised as a simple method of repairing stripped or damaged threads in any metal or valuable parts. Inserts are also used in new products such as die castings or plastics, where excessive stress on threads could cause damage or failure.

Precision inserts are helical coils of diamond shaped 18-8 stainless steel wire which meets or exceeds AMS-7245 specification. Inserts are sized to provide a precisely controlled interference fit in an oversized tapped hole. The tap used for this purpose is the same pitch as the original thread but has a larger diameter. When the insert is installed, the hole is returned to its original size.

Because the insert provides an enlarged bearing area, the restored fastening is stronger than the original. It is also more durable, since the stainless-steel thread is generally tougher than the original material. Precision inserts are corrosion resistant and their 22-microinch or better surface finish provides a smooth running, wear-resistant fastening.

Installation:

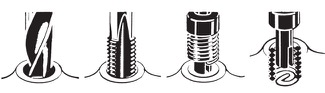

The first step in creating a new, stronger thread is cleaning up the original, dam- aged threads. This is done with a standard drill, the size of which is indicated on the Precision package. The hole is then tapped with an oversize (STI)* tap provided in each kit. Kits do not include drills. Drills are available at The Nutty Company. The free diameter of the Precision insert is larger than the new threaded hole, but it is easily “wound” into place with the inserting tool provided. Once in place, the insert tends to spring back into its original diameter, giving it a very strong grip in the hole. Finally, the driving tang is broken off by tapping downward with the end of the inserting tool. If necessary, inserts can be re- moved, using an extracting tool.

Drill... Tap... Insert... Remove Tang... Done.