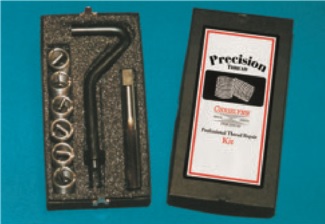

Helical Thread Kits for Thread Restoration

Professional helical thread repair kits provide comprehensive solutions for restoring damaged or stripped threads in various materials. These specialized kits include precision threaded inserts that create stronger, more durable threads than the original material. Each repair kit contains an installation tool specifically designed for proper insert placement and tension. Thread repair applications extend beyond basic maintenance to include cast iron engine blocks, aluminum components, and steel assemblies where original threads have failed. The helical design of these inserts distributes load evenly across multiple threads, often creating connections stronger than the original bolt specifications. Professional mechanics and machinists rely on these kits for critical repairs where thread integrity is essential. Whether restoring vintage equipment or repairing modern machinery, thread repair kits offer reliable solutions that extend component life. The versatility of these systems makes them indispensable for automotive, aerospace, and industrial applications requiring precision thread restoration.

FAQ

A complete thread repair kit includes helical threaded inserts, a specialized installation tool, drill bits, and tapping tools. Most kits contain multiple insert sizes and detailed instructions for proper thread repair procedures. Quality repair kit packages ensure you have everything needed to restore damaged threads in materials like cast iron and steel components requiring bolt connections.

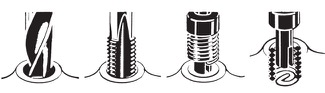

Using thread repair kits involves drilling out damaged threads, tapping new threads, and installing threaded inserts with the provided installation tool. The process works effectively on cast iron, aluminum, and steel materials. Each repair kit includes step-by-step instructions for proper thread repair, ensuring the restored bolt connection exceeds original strength specifications and performance requirements.

Yes, our thread repair kits accommodate both metric and standard thread specifications. Each repair kit includes threaded inserts and installation tool configurations for various nut & bolt sizes. These kits work effectively across different thread pitches and materials including cast iron applications. Professional thread repair solutions ensure compatibility with both measurement systems for comprehensive coverage.

Threaded inserts from thread repair kits are designed for permanent installation and typically cannot be reused. Once installed with the installation tool, the helical design locks into position for lasting thread repair. While the bolt can be removed repeatedly, the insert remains permanently fixed in cast iron or other materials, providing reliable long-term performance.