-

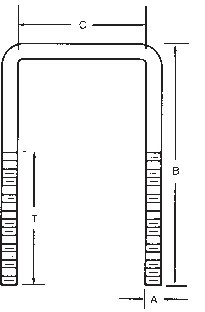

Galvanized Square U Bolt w/ nuts 3/8 x 2 x 3

SKU: GSUB23

$3.880each -

Galvanized Square U Bolt w/ nuts 3/8 x 2 x 5

SKU: GSUB25

$4.580each -

Galvanized Square U Bolt w/ nuts 3/8 x 2 x 7

SKU: GSUB27

$5.920each -

Galvanized Square U Bolt w/ nuts 3/8 x 4 x 3

SKU: GSUB43

$4.230each -

Galvanized Square U Bolt w/ nuts 3/8 x 4 x 5

SKU: GSUB45

$5.000each -

Galvanized Square U Bolt w/ nuts 3/8 x 4 x 7

SKU: GSUB47

$6.460each -

Galvanized Square U Bolt w/ nuts 3/8 x 6 x 5

SKU: GSUB65

$5.920each -

Galvanized Square U Bolt w/ nuts 3/8 x 6 x 7

SKU: GSUB67

$7.000each -

Galvanized Square U Bolt w/ nuts 3/8 x 6 x 9

SKU: GSUB69

$8.970each

Benefits of Using Galvanized U Bolts

Galvanized u bolts offer many benefits that make them superior fasteners for demanding applications. The galvanized coating provides exceptional corrosion resistance, extending the lifespan of these essential bolts far beyond standard steel alternatives. This protective zinc layer prevents rust and oxidation, ensuring reliable performance in harsh environments. The galvanized finish also enhances the overall appearance while maintaining structural integrity. These u bolts resist weathering, chemical exposure, and moisture damage, making them cost-effective solutions for long-term installations. The coating process strengthens the base metal while preserving thread quality and dimensional accuracy. Available in various diameter options and thread length configurations, galvanized u bolts accommodate diverse mounting requirements. Their durability reduces maintenance costs and replacement frequency, providing excellent value for construction, automotive, and industrial applications requiring dependable fastening solutions from Nutty Nuts.

Common Applications for Galvanized U Bolts

Galvanized u bolts serve critical roles across numerous industries due to their versatility and corrosion resistance. In plumbing systems, these fasteners secure pipe runs to structural supports, with the galvanized coating preventing deterioration from moisture exposure. Construction projects utilize these bolts for securing conduit, cable trays, and mechanical equipment where thread length and diameter specifications must match exact requirements. Automotive applications include exhaust system mounting, suspension components, and trailer hitches where galvanized protection ensures long-term reliability. Marine and outdoor installations benefit from the superior corrosion resistance when securing chain, fittings, and equipment exposed to harsh weather conditions. Industrial facilities use these fasteners for machinery mounting, conveyor systems, and structural connections. The versatility extends to residential applications including fence installation, playground equipment, and general construction projects. These screws-like fasteners work with standard nuts and washers, providing secure connections that maintain their integrity over extended service periods in challenging environments.

FAQ

Yes, galvanized u bolts are excellent for marine applications due to their corrosion-resistant coating. The galvanized finish protects these fasteners from saltwater exposure and coastal humidity. However, for extended marine exposure, ensure proper thread length and diameter selection, and use compatible nuts and washers for optimal performance in harsh marine environments.

Absolutely, galvanized u bolts are specifically designed for outdoor use. The galvanized coating provides superior weather resistance against rain, snow, and UV exposure. These bolts maintain their integrity in outdoor installations, making them ideal fasteners for securing pipe, chain, fittings, and various outdoor structures while resisting rust and corrosion effectively.

Most galvanized u bolts are sold separately from nuts and washers, allowing customers to select appropriate hardware for their specific applications. However, some suppliers offer complete kits including matching galvanized nuts and washers. Always verify thread specifications and diameter requirements to ensure proper fitment with compatible fasteners and accessories.

Yes, galvanized u bolts can secure copper pipe installations, but consider galvanic corrosion potential. Use appropriate insulating materials between the galvanized bolts and copper pipe to prevent electrolytic reactions. Ensure proper thread length and diameter selection for secure mounting. These fasteners work well with suitable fittings and protective measures in plumbing applications.