Reasons You Should Use Plastic Nuts

Sep 5th 2025

Introduction

When choosing fasteners for a project, the choice between metal and plastic components can impact performance, durability, and cost. For decades, metal nuts have long been the staple within the fastener market but plastic nuts are starting to gain popularity for their own set of benefits in certain applications.

Plastic nuts have great advantages and are perfect for a wide variety of projects where traditional metal fasteners might not be the best choice. Understanding when and why to use plastic nuts will allow you to make better decisions for your specific projects, which may save money or enhance performance.

What Makes Plastic Nuts Different

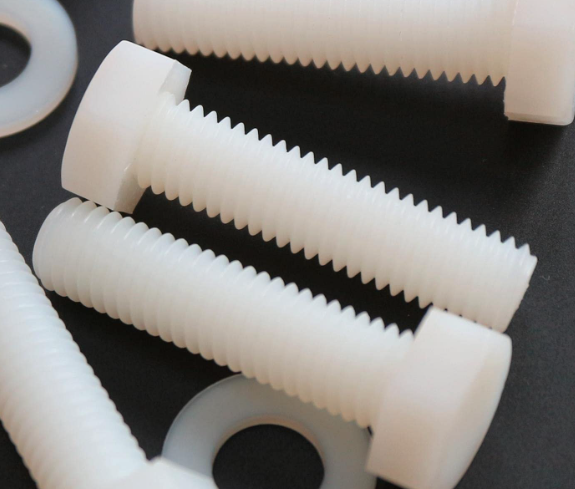

Plastic nuts are made of polymeric materials including nylon, polypropylene and engineering plastics. These are selected for use based on the requirements for the specific applications with properties that surpass or compliment those of metal in particular instances.

Unlike traditional nuts & bolts made from steel or aluminum, plastic nuts provide unique characteristics such as chemical resistance, electrical insulation, and weight reduction. The manufacturing process allows for precise tolerances while maintaining flexibility in design and customization options.

Plastic nuts incorporate the most advanced polymer science and modern manufacturing processes to create products that are strong, durable, and can outperform standard metal insert standards. Plastic nuts can be molded into complex shapes and configurations that would be difficult or expensive to achieve with metal fabrication methods.

Key Benefits of Using Plastic Nuts

Lightweight and Easy to Handle

A big advantage of plastic nuts is that they are a lot lighter than metal nuts. This can be of critical significance in applications where every ounce matters, such as aerospace, automotive, or portable equipment manufacturing.

In applications where lower weight is important for the system as a whole, plastic nuts can help achieve better fuel consumption in cars or allow portable equipment to be more manageable without compromising performance.

Corrosion Resistance

Plastic nuts are extremely corrosion-resistant thanks to their ability to withstand such harsh conditions – something that cannot be said for typical galvanized screws, or even stainless steel fasteners. They are corrosion and rust proof and will not deteriorate with time or exposure to the elements, so no need to worry about chipping away paint, changing colors, or breaking down when exposed to water chemicals, saltwater or other outdoor environmental conditions.

Plastic nuts are also chemical resistant, and can be used for applications involving acids, bases, and aliphatic hydrocarbons that would otherwise cause metal nuts to corrode.

Electrical Insulation

Plastic nuts possess good electric insulation properties and can be used in many electrical and electronic applications. And because plastic is non-conductive, you won’t have to worry about short-circuiting or electrical interference if it touches metal screws.

This insulation characteristic is especially advantageous for any connection to electronic equipment or anywhere the requirement for complete electrical isolation is necessary for safety or operational reasons. When used in combination with stainless steel self tapping screws or other metal fasteners, plastic nuts can offer selective insulation while keeping mechanical strength where it's needed.

Noise and Vibration Damping

The inherent properties of plastic materials provide natural vibration damping that can reduce noise and improve overall system performance. This can be useful for automotive and HVAC applications, or whenever vibration damping is required.

Plastic nuts can help prevent metal-to-metal contact that often creates unwanted noise and vibration. This damping effect can prolong the life of sensitive parts by minimizing wear, strain, or fatigue caused by vibration. In applications where quiet operation is essential, plastic nuts can significantly contribute to overall noise reduction compared to traditional metal fastener assemblies.

Cost-Effective Solution

Although individual costs may differ initially, plastic nuts offer better value with lower installation times, no corrosion-related maintenance, and longer service life in applicable uses.

The production of plastic nuts may be more cost effective for complicated shapes or larger production runs. This saving in cost can be passed onto the customers, and many will choose plastic nuts if they are on a tight budget. And when it comes to total cost of ownership, including maintenance, replacement, and labor costs, plastic nuts will often provide better value compared to metal nuts.

Versatility and Customization

Plastic nuts come in several colors; you can even color code systems or simply make your setup pleasing to the eye. And the ability to customize is particularly handy in apps where personal style is important.

The molding process allows for integration of additional features such as flanges, wings, or specialized gripping surfaces that would be difficult to achieve with machined metal nuts. These design options can eliminate the need for additional parts or manufacturing steps.

Ease of Installation

Plastic nuts tend to include design features allowing them to be installed more quickly and easily than conventional metallic nuts. Numerous plastic nuts have finger engagement portions or tool-engaging surfaces to facilitate operation.

The forgiving nature of plastic materials can accommodate slight misalignments or tolerance variations better than rigid metal components. This flexibility may help minimize assembly time, and enhance overall fit and finish.

Plastic nuts, when partnered with self drilling tek screws or other engineered fasteners offer enclosures and assembly solutions that simply can't be beat in ease of installation.

Environmental Advantages

A lot of plastic nuts are made from recyclable materials, thus contributing to green manufacturing. Plastic nuts can be recycled or otherwise disposed of more environmentally friendly than metal nuts.

In addition, the energy consumption of producing plastic nuts is generally lower than metal machining or casting. This lower energy use also leads to a smaller carbon footprint on the entire production process.

Plastic nuts don't have the need for protective coverings/coatings or hazardous treatments that may be of environment during manufacture or disposal, so they are a clearer choice for environmentally sound applications.

When to Choose Plastic Nuts Over Metal Nuts

If you require outstanding electrical insulation, are concerned about corrosion or need an option that’s lightweight then a plastic nut is the perfect choice. They are particularly useful in marine, outdoor and electronic components where curved metal fasteners could lead to rupture of the parent material.

Consider plastic nuts when working with sensitive materials that might be damaged by metal fasteners or in applications where noise and vibration reduction are important. They also make great all-purpose fasteners for both permanent and temporary installations.

Conclusion

Plastic nuts have their unique advantages and thus are used in many applications. With their corrosion resistance, ability to act as an electrical insulator, lightweight and low-cost price point there are many good reasons to use them on your next job.

There will always be room for regular nuts & bolts, but plastic nuts should not be disregarded if their benefits match the needs of a project. Understanding those advantages can help engineers and project managers make better-informed decisions on how best to balance performance against cost.