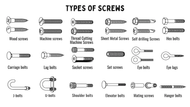

Types of Screws: A Comprehensive Guide to Choosing the Right Fastener

Oct 16th 2025

Walk into any hardware store and you'll face an overwhelming wall of fasteners—thousands of screws in different shapes, sizes, and configurations. Selecting the wrong screw can compromise your project's structural integrity, lead to material damage, or waste time and money. Understanding the various types of screws and their applications is essential whether you're a professional contractor or DIY enthusiast. Each application demands a specific fastener designed for optimal performance. At The Nutty Company, we believe successful projects begin with informed fastener selection, so let's explore screw types and help you choose the perfect fastener for your application.

Anatomy of a Screw

Understanding basic screw anatomy helps you select appropriate fasteners, as screws are designed for different functions in your projects. Every screw consists of four primary components: the head provides the interface for your driver tool, the shaft (or shank) extends from beneath the head, the threads wrap around the shaft in a helical pattern creating grip, and the point facilitates initial penetration.

Thread pitch refers to the distance between adjacent thread peaks. Coarse threads provide better grip in softer materials like wood, while fine threads offer superior holding strength in harder materials like metal. Screw diameter determines the fastener's strength and required pilot hole size. Length is measured from the bearing surface to the tip, ensuring adequate thread engagement along with proper thread cutting without excessive penetration.

Common Screw Types and Their Uses

Wood Screws

These feature coarse threads that grip wood fibers effectively, tapered shafts that reduce splitting, and sharp points for easy penetration. Wood Screws, including oval head screws, are ideal for furniture construction, cabinetry, and general woodworking applications.

Machine Screws

Machine screws have uniform threading along the entire shaft and require pre-tapped holes or matchingnuts and bolts. Machine Screws and lag bolts excel in metal-to-metal applications, electronics assembly, and machinery construction where repeatable, removable connections are needed.

Sheet Metal Screws

This type features sharp threads and pointed tips designed to penetrate thin metal sheets. Sheet metal screws, including washer head screws, work effectively for HVAC ductwork, metal roofing, and appliance assembly.

Drywall Screws

Drywall screws are engineered for attaching a gypsum board to studs. Drywall screws, including bugle head screws, feature bugle heads that sit slightly below the surface without tearing the paper facing. Coarse-thread versions work with wooden studs, while fine-thread variants grip metal framing.

Concrete Screws

Concrete screws are hardened fasteners designed for concrete, brick, and masonry. They require pre-drilled holes and feature aggressive threading for superior holding power in dense materials.

Deck Screws

Deck screws feature corrosion-resistant coatings or stainless steel construction to withstand outdoor weather exposure. Deck screws often include specialized points that reduce splitting in pressure-treated lumber.

Lag Screws

Lag screws are heavy-duty fasteners with hex heads driven by wrenches. Lag screws and carriage bolts require pre-drilled pilot holes and excel in structural applications like securing ledger boards, building timber frames, and attaching heavy equipment.

Specialty Screw Types

Self-tapping screws create their own threads as they're driven into materials like metal or plastic. They typically require pilot holes in harder materials and work well for assembling electronics, securing plastic components, and attaching brackets.

Self-drilling screws combine a drill bit point with threaded fastener functionality, drilling pilot holes and creating threads in a single operation. These fasteners dramatically accelerate installation in metal-to-metal connections, HVAC installations, and metal roofing.

Double-ended screws feature threads at both ends with a smooth central section. One end typically has wood screw threading while the other has machine screw threading, perfect for furniture legs and modular systems.

Security screws incorporate unique drive types designed to resist tampering and unauthorized removal. They feature special patterns like pentalobe or spanner heads that require specialized tools.

Mirror screws combine functionality with aesthetics, designed for mounting mirrors and decorative panels. They include decorative caps that conceal the screw head while providing an attractive finish.

Screw Head Styles and Drive Types

Common head styles include flat heads that sit flush with surfaces, pan heads with rounded tops, round heads creating dome-shaped profiles, truss heads offering wide bearing surfaces, and hex heads driven with wrenches for high torque applications.

Drive types determine tool compatibility and torque transfer. Slotted drives feature single straight slots but strip easily. Phillips drives, which include Phillips head screws, incorporate cross-shaped recesses designed to cam out under high torque. Pozidriv drives improve upon Phillips with better engagement and reduced cam-out. Torx drives feature six-pointed star patterns that virtually eliminate cam-out and transfer high torque efficiently.

Choose head and drive combinations based on your application needs. Flush mounting requires flat heads, while high-torque installation benefits from Torx or hex drives. Consider accessibility, aesthetic requirements, and tool availability when making selections.

Material and Coating Considerations

Common screw materials include carbon steel for economical strength in indoor applications, stainless steel for superior corrosion resistance in marine and outdoor environments, brass for decorative hardware with moderate corrosion resistance, and aluminum for lightweight applications.

Protective coatings enhance performance and longevity. Zinc plating provides economical corrosion protection for moderate moisture exposure. Hot-dip galvanizing offers enhanced resistance for outdoor applications. Protective coatings enhance performance and longevity, with heads designed for various applications. Black oxide coating provides minimal protection but attractive matte appearance. Ceramic coatings deliver exceptional corrosion and heat resistance.

Select materials and coatings based on your environment. Outdoor applications require stainless steel or galvanized fasteners. Coastal environments need marine-grade stainless steel. Indoor climate-controlled spaces can use standard zinc-plated steel. High-load structural applications need high-strength steel alloys.

Choosing the Right Screw for Your Project

Successful fastener selection balances multiple considerations. Material type serves as the primary criterion—wood applications need wood screws with coarse threads, metal substrates demand sheet metal screws or machine screws with nuts and bolts, and masonry materials require specialized concrete screws.

Load requirements determine necessary screw diameter and length. Light-duty applications use smaller gauge fasteners, while heavy-duty structural applications demand large-diameter lag screws or bolted connections. Always calculate expected loads with adequate safety margins.

Environmental conditions dramatically impact longevity. Indoor controlled environments allow standard zinc-plated fasteners. Outdoor applications require corrosion-resistant coatings or stainless steel. Environmental conditions dramatically impact longevity, and other materials may require specific fasteners. Coastal locations need marine-grade stainless steel.

Selection tips include starting with the material being fastened, calculating required length for adequate thread engagement, choosing diameter based on load requirements, selecting head style based on desired finish, and determining material and coating based on environmental exposure. The Nutty Company offers expert consultation for complex fastening challenges.

Conclusion

Understanding the diverse types of screws and their applications empowers you to make informed selections that ensure project success. From basic wood screws to specialized self-drilling fasteners, from corrosion-resistant deck screws to socket screws, the right fastener makes all the difference in performance and longevity.

Proper fastener selection considers material compatibility, load requirements, environmental conditions, and installation access. Taking time to identify the optimal screw type prevents problems ranging from minor inconveniences to structural failures.

The Nutty Company stocks comprehensive inventories of most screws across all categories and offers nuts and bolts in matching sizes. Our technical team provides expert guidance for your specific requirements, ensuring you choose the right types of screws for lasting results.

FAQs

How many types of screws are there?

There are hundreds of screw variations, but most applications use 10-15 common types including wood screws, machine screws, sheet metal screws, drywall screws, deck screws, concrete screws, and lag screws. There are hundreds of screw variations, including those with a hexagonal head. Specialty screws address specific challenges like self-drilling for metal or security screws for tamper resistance. The Nutty Company helps customers identify the specific types that best match their project requirements.

What is the difference between wood screws and machine screws?

Wood screws have tapered shafts with coarse threads, sharp points, and smooth shanks near the head. They're designed to be driven directly into wood. Machine screws have uniform diameter with fine threads, blunt ends, and require pre-tapped holes or mating nuts and bolts. Machine screws excel in metal-to-metal connections and removable assemblies, while wood screws optimize wood-to-wood fastening.

What screw head types are there?

Common head types include flat (countersunk) heads that sit flush, pan heads with rounded tops, round heads creating dome profiles, truss heads with wide bearing surfaces, hex heads for high torque, button heads with smooth profiles, and various specialty heads. Drive types include slotted, Phillips, Pozidriv, Torx, hex socket, and security variants. Selection depends on whether fasteners should sit flush or protrude, required bearing surface, available tools, and aesthetic requirements.

How do I choose the right screw material?

Choose based on environmental exposure and load requirements. Indoor climate-controlled applications use carbon steel with zinc plating. Outdoor applications need hot-dip galvanizing or stainless steel. Coastal environments require marine-grade stainless steel (grade 316). High-load structural applications need high-strength steel alloys. Chemical exposure requires compatible materials—typically stainless steel. Weight-critical applications might specify aluminum or titanium. Choose based on environmental exposure and load requirements, and consider using an allen wrench for specific fasteners. The Nutty Company provides detailed material specifications and application guidance to balance performance with budget constraints.